Tantalum pentachloride (TaCl₅) – often simply called tantalum chloride – is a white, water-soluble crystalline powder that serves as a versatile precursor in many high-technology processes. In metallurgy and chemistry, it provides an exquisite source of pure tantalum: suppliers note that “Tantalum(V) chloride is an excellent water soluble crystalline tantalum source”. This reagent finds critical application wherever ultrapure tantalum must be deposited or converted: from microelectronic atomic layer deposition (ALD) to corrosion-protective coatings in aerospace. In all these contexts, material purity is paramount – in fact, high-performance applications commonly require TaCl₅ at “>99.99% purity”. The EpoMaterial product page (CAS 7721-01-9) highlights exactly such high-purity TaCl₅ (99.99%) as a starting material for advanced tantalum chemistry. In short, TaCl₅ is a linchpin in the fabrication of cutting-edge devices – from 5nm semiconductor nodes to energy-storage capacitors and corrosion-resistant parts – because it can reliably deliver atomically pure tantalum under controlled conditions.

Figure: High-purity tantalum chloride (TaCl₅) is typically a white crystalline powder used as a source of tantalum in chemical vapor deposition and other processes.

Chemical Properties and Purity

Chemically, tantalum pentachloride is TaCl₅, with a molecular weight of 358.21 and a melting point around 216 °C. It is sensitive to moisture and undergoes hydrolysis, but under inert conditions it sublimes and decomposes cleanly. TaCl₅ can be sublimed or distilled to achieve ultra-high purity (often 99.99% or greater). For semiconductor and aerospace use, such purity is non-negotiable: trace impurities in the precursor would end up as defects in thin films or alloy deposits. High-purity TaCl₅ ensures that deposited tantalum or tantalum compounds have minimal contamination. Indeed, manufacturers of semiconductor precursors explicitly tout processes (zone refining, distillation) to achieve “>99.99% purity” in TaCl₅, meeting “semiconductor-grade standards” for defect-free deposition.

The EpoMaterial listing itself underscores this demand: its TaCl₅ product is specified at 99.99% purity, reflecting exactly the grade needed for advanced thin-film processes. Packaging and documentation typically include a Certificate of Analysis confirming metal content and residuals. For example, one CVD study used TaCl₅ “with purity of 99.99%” as supplied by a specialty vendor, demonstrating that top laboratories source the same high-grade material. In practice, sub-10 ppm levels of metallic impurities (Fe, Cu, etc.) are required; even 0.001–0.01% of an impurity can ruin a gate dielectric or a high-frequency capacitor. Thus, purity isn’t just marketing – it is essential to achieve the performance and reliability demanded by modern electronics, green energy systems, and aerospace components.

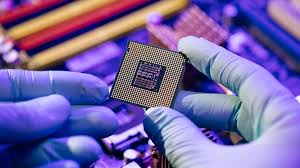

Role in Semiconductor Fabrication

In semiconductor manufacturing, TaCl₅ is predominantly used as a chemical vapor deposition (CVD) precursor. Hydrogen reduction of TaCl₅ yields elemental tantalum, enabling the formation of ultrathin metal or dielectric films. For example, a plasma-assisted CVD (PACVD) process showed that

can deposit high-purity tantalum metal on substrates at moderate temperatures. This reaction is clean (producing only HCl as a byproduct) and yields conformal Ta films even in deep trenches. Tantalum metal layers are used as diffusion barriers or adhesion layers in interconnect stacks: a Ta or TaN barrier prevents copper migration into silicon, and TaCl₅-based CVD is one route to deposit such layers uniformly over complex topologies.

Beyond pure metal, TaCl₅ is also an ALD precursor for tantalum oxide (Ta₂O₅) and tantalum silicate films. Atomic Layer Deposition (ALD) techniques use TaCl₅ pulses (often with O₃ or H₂O) to grow Ta₂O₅ as a high-κ dielectric. For instance, Jeong et al. demonstrated ALD of Ta₂O₅ from TaCl₅ and ozone, achieving ~0.77 Å per cycle at 300 °C. Such Ta₂O₅ layers are potential candidates for next-generation gate dielectrics or memory (ReRAM) devices, thanks to their high dielectric constant and stability. In emerging logic and memory chips, material engineers increasingly rely on TaCl₅-based deposition for “sub-3nm node” technology: a specialty supplier notes that TaCl₅ is an “ideal precursor for CVD/ALD processes to deposit tantalum-based barrier layers and gate oxides in 5nm/3nm chip architectures”. In other words, TaCl₅ sits at the heart of enabling the latest Moore’s Law scaling.

Even in photoresist and patterning steps, TaCl₅ finds uses: chemists use it as a chlorinating agent in etch or lithography processes to introduce tantalum residues for selective masking. And during packaging, TaCl₅ can create protective Ta₂O₅ coatings on sensors or MEMS devices. In all these semiconductor contexts, the key is that TaCl₅ can be precisely delivered in vapor form, and its conversion produces dense, adherent films. This underlines why semiconductor fabs specify only the highest-purity TaCl₅ – because even ppb-level contaminants would appear as defects in chip gate dielectrics or interconnects.

Enabling Sustainable Energy Technologies

Tantalum compounds play a vital role in green-energy and energy-storage devices, and tantalum chloride is an upstream enabler of those materials. For example, tantalum oxide (Ta₂O₅) is used as the dielectric in high-performance capacitors – notably tantalum electrolytic capacitors and tantalum-based supercapacitors – which are critical in renewable-energy systems and power electronics. Ta₂O₅ has a high relative permittivity (ε_r ≈ 27), enabling capacitors with high capacitance per volume. Industry references note that “Ta₂O₅ dielectric enables higher frequency AC operation… making these devices suitable for use in power supplies as bulk smoothing capacitors”. In practice, TaCl₅ can be converted to finely divided Ta₂O₅ powder or thin films for these capacitors. For example, an electrolytic capacitor’s anode is typically sintered porous tantalum with a Ta₂O₅ dielectric grown via electrochemical oxidation; the tantalum metal itself could come from TaCl₅-derived deposition followed by oxidation.

Beyond capacitors, tantalum oxides and nitrides are being explored in battery and fuel cell components. Recent research points to Ta₂O₅ as a promising Li-ion battery anode material due to its high capacity and stability. Tantalum-doped catalysts can improve water-splitting for hydrogen generation. Although TaCl₅ itself is not added to batteries, it is a route to prepare nano-tantalum and Ta-oxide via pyrolysis. For example, suppliers of TaCl₅ list “supercapacitor” and “high CV (coefficient of variation) tantalum powder” in their application list, hinting at advanced energy-storage uses. One white paper even cites TaCl₅ in coatings for chlor-alkali and oxygen electrodes, where a Ta-oxide overlayer (mixed with Ru/Pt) extends electrode life by forming robust conductive films.

In large-scale renewables, tantalum components increase system resilience. For instance, Ta-based capacitors and filters stabilize voltage in wind turbines and solar inverters. Advanced wind-turbine power electronics may use Ta-containing dielectric layers fabricated via TaCl₅ precursors. A generic illustration of the renewable landscape:

Figure: Wind turbines at a renewable energy site. High-voltage power systems in wind and solar farms often rely on advanced capacitors and dielectrics (e.g. Ta₂O₅) to smooth power and improve efficiency. Tantalum precursors like TaCl₅ underpin the fabrication of these components.

Furthermore, tantalum’s corrosion resistance (especially its Ta₂O₅ surface) makes it attractive for fuel cells and electrolyzers in the hydrogen economy. Innovative catalysts use TaOx supports to stabilize precious metals or act as catalysts themselves. In sum, sustainable-energy technologies — from smart grids to EV chargers — often depend on tantalum-derived materials, and TaCl₅ is a key feedstock for making them at high purity.

Aerospace and High-Precision Applications

In aerospace, tantalum’s value lies in extreme stability. It forms an impervious oxide (Ta₂O₅) that protects against corrosion and high-temperature erosion. Parts that see aggressive environments — turbines, rockets, or chemical-processing equipment — use tantalum coatings or alloys. Ultramet (a high-performance materials company) uses TaCl₅ in chemical vapor processes to diffuse Ta into superalloys, vastly improving their resistance to acid and wear. The result: components (e.g. valves, heat exchangers) that can withstand harsh rocket fuels or corrosive jet fuels without degradation.

High-purity TaCl₅ is also used to deposit mirror-like Ta coatings and optical films for space optics or laser systems. For example, Ta₂O₅ is used in anti-reflective coatings on aerospace glass and precision lenses, where even tiny impurity levels would compromise optical performance. A supplier brochure highlights that TaCl₅ enables “anti-reflective and conductive coatings for aerospace-grade glass and precision lenses”. Similarly, advanced radar and sensor systems use tantalum in their electronics and coatings, all starting from high-purity precursors.

Even in additive manufacturing and metallurgy, TaCl₅ contributes. While bulk tantalum powder is used in 3D printing of medical implants and aerospace parts, any chemical etching or CVD of those powders often relies on chloride chemistry. And high-purity TaCl₅ itself can be combined with other precursors in novel processes (e.g. organometallic chemistry) to create complex superalloys.

Overall, the trend is clear: the most demanding aerospace and defense technologies insist on “military or optical grade” tantalum compounds. EpoMaterial’s offering of “mil-spec”–grade TaCl₅ (with USP/EP compliance) caters to these sectors. As one high-purity supplier states, “our tantalum products are critical components for the manufacturing of electronics, superalloys in the aerospace sector, and corrosion resistance coating systems”. The advanced manufacturing world simply cannot function without the ultra-clean tantalum feedstocks that TaCl₅ provides.

Importance of 99.99% Purity

Why 99.99%? The simple answer: because in technology, impurities are fatal. At the nanoscale of modern chips, a single contaminant atom can create a leakage path or trap charge. At the high voltages of power electronics, an impurity can initiate dielectric breakdown. In corrosive aerospace environments, even ppm-level catalyst accelerants can attack metal. Therefore, materials like TaCl₅ must be “electronics-grade.”

Industry literature underscores this. In the plasma CVD study above, the authors explicitly chose TaCl₅ “because of its mid-range optimal [vapor] values” and note that they used “99.99% purity” TaCl₅. Another supplier write-up boasts: “Our TaCl₅ achieves >99.99% purity through advanced distillation and zone-refining… meeting semiconductor-grade standards. This guarantees defect-free thin-film deposition”. In other words, process engineers depend on that four-nines purity.

High purity also affects process yields and performance. For instance, in ALD of Ta₂O₅, any residual chlorine or metal impurities could alter film stoichiometry and dielectric constant. In electrolytic capacitors, trace metals in the oxide layer could cause leakage currents. And in Ta-alloys for jet engines, extra elements can form undesirable brittle phases. Consequently, material datasheets often specify both the chemical purity and the allowable impurity (typically < 0.0001%). The EpoMaterial spec sheet for 99.99% TaCl₅ shows impurity totals below 0.0011% by weight, reflecting these tight standards.

Market data reflects the value of such purity. Analysts report that 99.99% tantalum commands a substantial premium. For example, one market report notes tantalum’s price is driven higher by the demand for “99.99% purity” material. Indeed, the global tantalum market (metal and compounds combined) was about $442 million in 2024, with growth to ~$674 million by 2033 – much of that demand comes from high-tech capacitors, semiconductors, and aerospace, all requiring very pure Ta sources.

Tantalum chloride (TaCl₅) is far more than a curious chemical: it is a keystone of modern high-tech manufacturing. Its unique combination of volatility, reactivity, and ability to yield pristine Ta or Ta-compounds makes it indispensable for semiconductors, sustainable energy devices, and aerospace materials. From enabling the deposition of atomically thin Ta films in the latest 3nm chips, to supporting the dielectric layers in next-generation capacitors, to forming the corrosion-proof coatings on aircraft, high-purity TaCl₅ is quietly everywhere.

As demand for green energy, miniaturized electronics, and high-performance machinery grows, the role of TaCl₅ will only increase. Suppliers like EpoMaterial recognize this by offering TaCl₅ in 99.99% purity for exactly these applications. In short, tantalum chloride is a specialized material at the heart of “cutting-edge” technology. Its chemistry may be old (discovered in 1802), but its applications are the future.

Post time: May-26-2025