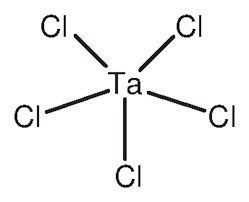

Tantalum chloride, often called tantalum Chloride (TaCl₅), is a white, crystalline inorganic compound that plays a pivotal role in advanced chemical and electronic industries. In its pure form (formula TaCl₅) it is a white powder and serves as the starting material for a wide range of tantalum-based chemicals. TaCl₅ is highly reactive – it readily hydrolyzes in air to form tantalum oxychloride and ultimately tantalum pentoxide – so it must always be handled under anhydrous (water-free) conditions. This sensitivity to moisture means TaCl₅ is typically stored and shipped in sealed, dry containers.

In this article, we explore two main themes: first, the principal uses of tantalum chloride in industry and research; and second, how TaCl₅ is produced and extracted from raw materials. The discussion will be accessible to non-specialists, with clear explanations and suggestions of where a diagram or table might aid understanding. Wherever possible, we will reference technical sources to ensure accuracy, including information from specialist product literature.

Major Uses of Tantalum Chloride

Tantalum pentachloride is a versatile chemical intermediate and catalyst. Because it is a strong Lewis acid (an electron-pair acceptor), TaCl₅ is used in various synthetic reactions and materials processes. Some key applications include:

● Catalyst in organic synthesis: TaCl₅ acts as an electrophilic catalyst much like aluminum chloride (AlCl₃). It is used to promote specialized reactions, for example polymerizations or Friedel–Crafts type acylations and alkylations. It has been employed as a catalyst for the polycyclotrimerization of certain alkynes (polymer-forming reactions) and in preparing chloro-aryloxide compounds.

● Precursor to tantalum oxides and oxychlorides: Because TaCl₅ hydrolyzes to tantalum oxychloride (TaOCl₃) and then to tantalum pentoxide (Ta₂O₅), it is routinely used to make those materials. Ta₂O₅ is a key dielectric oxide used in high-value capacitors and coatings. In practice, TaCl₅ can be converted (by adding water or ammonia) into extremely pure tantalum oxides or into ammonium oxychloride which are then calcined to oxides. This pathway is one reason TaCl₅ is a critical feedstock for the tantalum industry.

● Semiconductor materials deposition: In the microelectronics industry, TaCl₅ is used as a precursor gas for chemical vapor deposition (CVD) and atomic layer deposition (ALD) of tantalum-containing thin films. For example, TaCl₅ vapor can be reacted with ammonia or nitrogen plasmas to deposit thin films of tantalum nitride (TaN), a material used as a diffusion barrier or electrode in integrated circuits. It is also used to deposit tantalum pentoxide films for capacitors. Its stability in chlorine environments makes it ideal for these high-temperature processes.

● Electronics and alloys: Ultimately, much of the TaCl₅ produced is converted to tantalum metal for use in electronic components. Tantalum capacitors – tiny capacitors used in cell phones, laptops, and other electronics – rely on high-purity Ta₂O₅ (derived from TaCl₅) as the dielectric. TaCl₅ itself is a stepping stone: it can be reduced (for example by sodium or aluminum) to yield fine tantalum powder, which is then made into capacitors and high-temperature alloys. In short, TaCl₅ is critical to making tantalum metal and thus to the entire tantalum capacitor industry. (A table or flowchart summarizing the conversion of TaCl₅ into metal, oxide, and nitride products could help readers visualize these pathways.)

In summary, tantalum pentachloride is used wherever extremely pure tantalum compounds or films are needed. It enables both organic chemistry processes (as a catalyst and chlorinating agent) and materials processes (deposition of films, synthesis of oxides). According to manufacturer data, TaCl₅ “acts as a starting material for new edge-bridged octahedral M₆ cluster compounds” and is involved in making tantalum(V) oxychloride and pentoxide. Its electrophilic (electron-loving) nature, similar to that of classic catalysts like AlCl₃, underscores its role in advanced chemistry.

How Tantalum Chloride is Prepared

Producing tantalum pentachloride involves chlorinating tantalum in some form. There are two main routes: chlorination of tantalum metal, and chlorination of tantalum compounds (usually oxides). In all cases, the reaction must be done in a dry, oxygen-free environment. The basic processes are:

● Direct chlorination of metallic tantalum: Finely divided tantalum metal (often filings or powder) is heated in a stream of chlorine gas. At temperatures around 170–250 °C, the chlorine reacts with the metal to form TaCl₅ vapor:

2 Ta+5 Cl2⟶2 TaCl5.2\,Ta + 5\,Cl_2 \longrightarrow 2\,TaCl_5.

This exothermic reaction quickly converts metal to chloride. In practice, the tantalum is placed in a furnace or reactor and Cl₂ gas is flowed over it at controlled temperature. The resulting TaCl₅ vapor is then condensed into a liquid or solid as it cools. (A related method uses hydrogen chloride gas (HCl) instead of Cl₂, but this requires higher temperature – around 400 °C – to drive the reaction.)

● Indirect chlorination (from oxides): Often, high-purity tantalum metal is not readily available or is too expensive. Instead, one can start with tantalum pentoxide (Ta₂O₅), which is abundant in ore concentrates. Ta₂O₅ can be converted to TaCl₅ by using a chlorinating agent such as thionyl chloride (SOCl₂). The reaction is:

Ta2O5+5 SOCl2→240∘C2 TaCl5+5 SO2.\text{Ta}_2\text{O}_5 + 5\,SOCl_2 \xrightarrow{240^\circ\text{C}} 2\,TaCl_5 + 5\,SO_2.

In this method, solid Ta₂O₅ is mixed with liquid SOCl₂ and heated (around 240 °C). The SOCl₂ effectively converts the oxide to chloride, producing sulfur dioxide gas as a byproduct. This indirect route is useful when working with oxide powders and can yield very pure TaCl₅.

Both methods above produce TaCl₅ gas, which then must be condensed and purified. In practice, the chlorine-containing gas is cooled so that TaCl₅ liquefies (boiling point ~239 °C). Distillation is often used to separate TaCl₅ from any impurities or lower-boiling materials. For example, when synthesizing in a lab, one might pass the gas through a cold trap or a series of condensers. After condensation, the product is dried (heated gently under vacuum) to remove traces of moisture. This results in a high-purity white solid. (A table summarizing these synthesis methods – listing reactants, conditions, and products – could help compare the routes side-by-side.)

● Industrial extraction from ore: At large scale, tantalum is often obtained from minerals like tantalite or coltan, which contain both tantalum and niobium oxides. In one industrial process, the ore concentrate is blended with carbon (coke) and reacted with chlorine gas at high temperature. This carbochlorination converts the oxides into volatile chlorides. Initially, a mixture of titanium, niobium, and tantalum chlorides forms and condenses to a liquid called “titanium-niobium-tantalum oxichloride.” This liquid is fractionally distilled: first titanium tetrachloride (TiCl₄) is removed (boiling 136 °C), leaving mostly niobium and tantalum chlorides. The remaining mix is then further chlorinated (if needed) to convert any oxychlorides into pentachlorides. Finally, the niobium chloride (NbCl₅) and tantalum chloride (TaCl₅) are separated by fractional distillation, since TaCl₅ boils at 239 °C and NbCl₅ at 248 °C. The end result is purified TaCl₅. This TaCl₅ is often then reacted with aqueous ammonia to precipitate ammonium tantalum fluoride or oxychloride, which on calcination yields ultra-pure Ta₂O₅. In essence, TaCl₅ serves as an intermediate in refining tantalum from its ores. A flowchart illustrating these steps – from raw ore to TaCl₅ to oxide – would be useful for readers to visualize the industrial process.

In summary, tantalum chloride is produced by halogenation of tantalum metal or compounds. Direct chlorination of Ta metal with Cl₂ is the simplest lab route, while industrial processes often use high-temperature chlorination of tantalum oxide concentrates with carbon (carbochlorination) or with other chlorinating agents. The gaseous TaCl₅ is then condensed and distilled to high purity. Notably, one manufacturer’s technical note emphasizes that TaCl₅ is used in the “chlorination of organic substances” and as a “chemical intermediate” in producing pure tantalum metal, underscoring its role as both a reagent and a key intermediate.

Summary

Tantalum Chloride (TaCl₅) is a key chemical intermediate in the tantalum industry. It is used extensively as a starting material to make other tantalum compounds (oxides, nitrides, metals) and serves as a Lewis acid catalyst in specialized chemical reactions. Common applications range from electronics (tantalum capacitors, semiconductor thin films) to advanced organic synthesis. Because TaCl₅ is moisture-sensitive and corrosive, handling it requires strict dry conditions.

The production of TaCl₅ involves chlorinating tantalum in some form. In the lab, this means reacting Ta metal or oxide with chlorine (or chlorine sources). In industry, it means using high-temperature chlorination of ore concentrates, often with carbon, followed by distillation. All routes require careful purification to isolate pure TaCl₅ and remove byproducts.

Understanding both the uses and production methods of tantalum chloride is essential for appreciating its role in modern technology. By integrating chemical synthesis details with practical applications (and providing visual aids where helpful), readers can see how this seemingly obscure compound is in fact a linchpin of tantalum-based materials in electronics, chemistry, and beyond.

Post time: May-30-2025