Gadolinium zirconate (Gd₂Zr₂O₇), also known as zirconate gadolinium, is a rare-earth oxide ceramic prized for its extremely low thermal conductivity and exceptional thermal stability. In simple terms, it’s a “super-insulator” at high temperatures – heat doesn’t flow through it easily. This property makes it ideal for thermal barrier coatings (TBCs), which protect engine and turbine components from extreme heat. As the world pushes toward cleaner, more efficient energy, materials like gadolinium zirconate are gaining attention: they help engines run hotter and more efficiently, burning less fuel and cutting emissions.

What Is Gadolinium Zirconate?

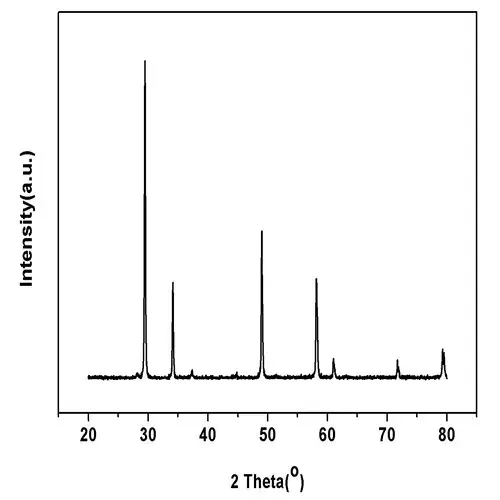

Chemically, gadolinium zirconate is a pyrochlore-structured ceramic: it contains gadolinium (Gd) and zirconium (Zr) cations arranged in a three-dimensional lattice with oxygen. Its formula is often written Gd₂Zr₂O₇ (or sometimes Gd₂O₃·ZrO₂). This ordered crystal (pyrochlore) can transform into a more disordered fluorite structure at very high temperatures (~1530 °C). Importantly, each formula unit has an oxygen vacancy – a missing oxygen atom – which strongly scatters heat-carrying phonons. That structural quirk is one reason gadolinium zirconate conducts heat much less effectively than more common ceramics.

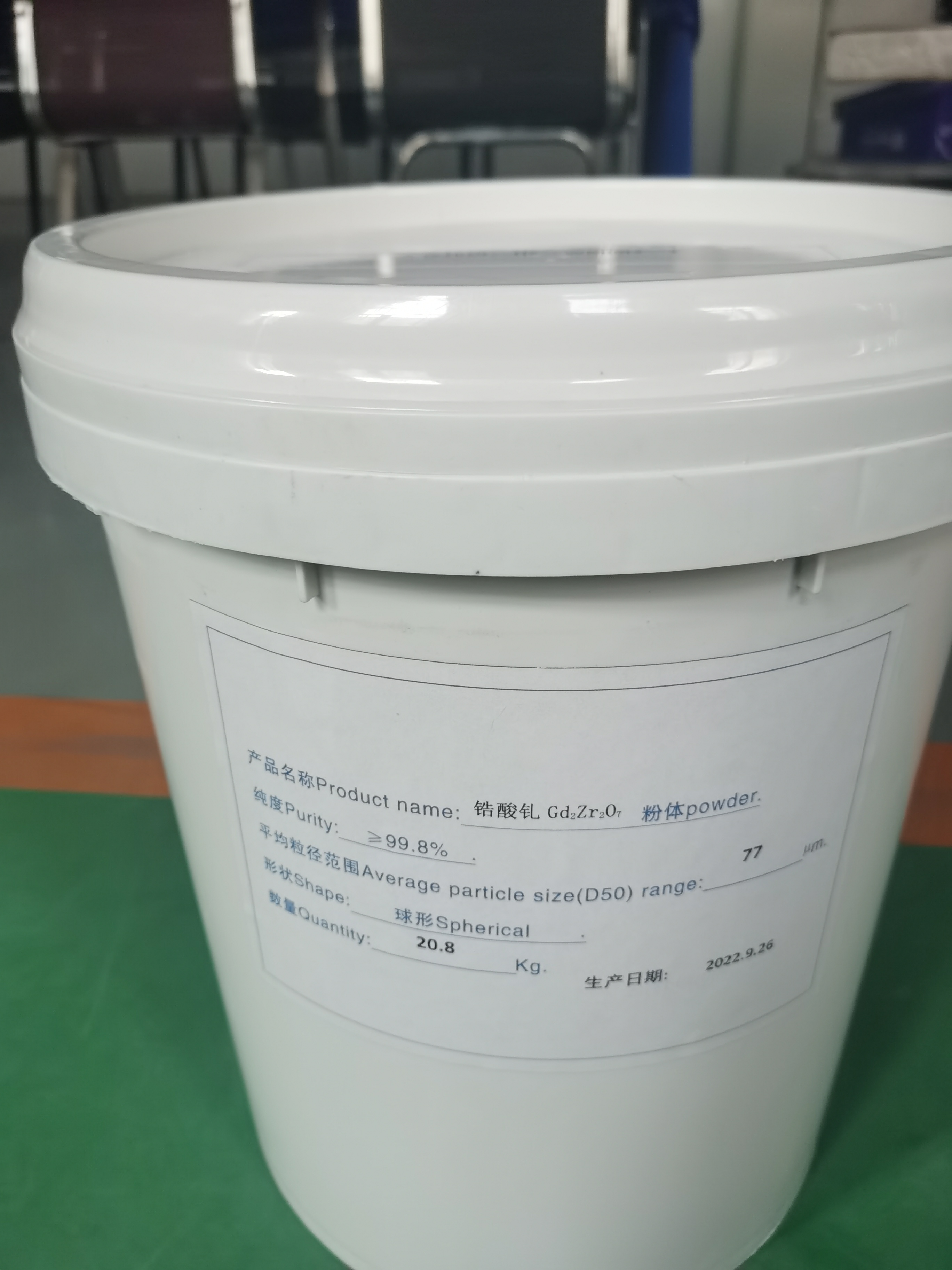

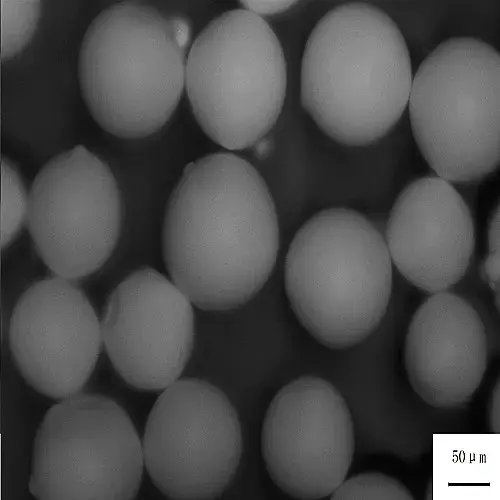

Epomaterial and other suppliers make high-purity Gd₂Zr₂O₇ powder (often 99.9% pure, CAS 11073-79-3) specifically for TBC applications. For example, Epomaterial’s product page highlights “Gadolinium Zirconate is an oxide-based ceramic with low thermal conductivity” used in plasma-spray TBCs. Such descriptions underscore that its low-κ trait is central to its value. (Indeed, Epomaterial’s listing for “Zirconate Gadolinium (GZO)” powder shows it as a white, oxide-based thermal spray material.)

Why Low Thermal Conductivity Matters?

Thermal conductivity (κ) measures how readily heat flows through a material. Gadolinium zirconate’s κ is astonishingly low for a ceramic, especially at engine-like temperatures. Studies report values on the order of 1–2 W·m⁻¹·K⁻¹ at around 1000 °C. For context, conventional yttria-stabilized zirconia (YSZ) – the decades-old TBC standard – is about 2–3 W·m⁻¹·K⁻¹ at similar temperatures. In one study, Wu et al. found Gd₂Zr₂O₇’s conductivity to be ~1.6 W·m⁻¹·K⁻¹ at 700 °C, versus ~2.3 for YSZ under the same conditions. Another report notes a range of 1.0–1.8 W·m⁻¹·K⁻¹ at 1000 °C for gadolinium zirconate, “lower than YSZ”. In practical terms, this means a GdZr₂O₇ layer will let far less heat through than an equivalent YSZ layer at high temperature – a huge advantage for insulation.

Key Benefits of Gadolinium Zirconate (Gd₂Zr₂O₇):

Ultra-low thermal conductivity: ~1–2 W/m·K at 700–1000 °C, significantly below YSZ.

High phase stability: Stays stable up to ~1500 °C, far above YSZ’s ~1200 °C limit.

High thermal expansion: Expands more on heating than YSZ, which can reduce stresses in coatings.

Oxidation and corrosion resistance: Forms stable oxide phases; resists molten CMAS deposits better than YSZ (rare-earth zirconates tend to react with silicate deposits and form protective crystals).

Eco-impact: By improving engine/turbine efficiency, it helps reduce fuel consumption and emissions.

Each of these factors ties back to energy efficiency and sustainability. Because GdZr₂O₇ insulates better, engines need less cooling and can run hotter, translating directly into higher efficiency and lower fuel use. As a University of Virginia study observes, better TBC efficiency means burning “less fuel to generate the same amount of energy, resulting in … lower greenhouse gas emissions”. In short, gadolinium zirconate can help machines run cleaner.

Thermal Conductivity in Detail

To answer the key question “What is the thermal conductivity of gadolinium zirconate?”: It is very low for a ceramic, roughly 1–2 W·m⁻¹·K⁻¹ in the 700–1000 °C range. This has been confirmed by multiple studies. Wu et al. report ≈1.6 W/m·K at 700 °C for Gd₂Zr₂O₇, whereas YSZ measured ≈2.3 under the same conditions. Shen et al. note “1.0–1.8 W/m·K at 1000 °C”. In contrast, YSZ’s conductivity at 1000 °C is typically around 2–3 W/m·K. In everyday terms, imagine two insulation tiles on a hot stove: the one with GdZr₂O₇ keeps the backside much cooler than a YSZ tile of the same thickness.

Why is Gd₂Zr₂O₇ so much lower? Its crystal structure inherently impedes heat flow. The oxygen vacancies in each unit cell scatter phonons (heat carriers), and gadolinium’s heavy atomic weight further damps lattice vibrations. As one source explains, “oxygen vacancy increases phonon scattering and decreases thermal conductivity”. Manufacturers exploit this property: Epomaterial’s catalog notes GdZr₂O₇ is used in plasma-sprayed thermal barrier coatings specifically because of its low κ. In essence, its microstructure traps heat inside, protecting the underlying metal.

Thermal Barrier Coatings (TBCs) and Applications

Thermal barrier coatings are ceramic layers applied to metal parts that face hot gases (like turbine blades). By reflecting and insulating against heat, TBCs let engines and turbines operate at higher temperatures without melting. Gadolinium zirconate has emerged as a next-generation TBC material, complementary to or replacing YSZ in extreme conditions. Key reasons include its stability and insulation:

Extreme-temperature performance: Gd₂Zr₂O₇’s pyrochlore-to-fluorite phase transition occurs near 1530 °C, well above YSZ’s ~1200 °C. This means GdZr₂O₇ coatings remain intact at the scorching temperatures of modern turbine hot sections.

Resistance to hot corrosion: Tests show that rare-earth zirconates like GdZr₂O₇ react with molten engine debris (so-called CMAS: calcium-magnesium-alumino-silicate) to form stable crystalline seals, preventing deep infiltration. This is a big deal in jet engines flying through volcanic ash or sand.

Layered coatings: Engineers often pair GdZr₂O₇ with YSZ in multi-layer stacks. For example, a thin YSZ underlayer can buffer thermal expansion, while a GdZr₂O₇ top layer provides superior insulation and stability. Such “double-layer” TBCs can exploit the best of both materials.

Applications: Because of these traits, GdZr₂O₇ is ideal for next-generation engines and aerospace components. Jet engine manufacturers and rocket designers are interested in it, since higher temperature tolerance means better thrust and efficiency. In gas turbines for power plants (including those paired with renewable energy sources), using GdZr₂O₇ coatings can squeeze more power from the same fuel. For instance, NASA notes that to reach the “higher temperatures necessary for enhanced efficiency of gas turbine engines,” YSZ is inadequate, and materials like gadolinium zirconate are being studied instead.

Even beyond turbines, any system needing heat protection at extreme temperatures can benefit. This includes hypersonic flight vehicles, high-performance automotive engines, and even experimental solar thermal power receivers where sunlight is concentrated to extreme heat. In each case, the goal is the same: insulate hot parts to improve overall efficiency. Better insulation means less cooling required, smaller radiators, lighter designs, and crucially, burning less fuel or using less input energy.

Sustainability and Energy Efficiency

The environmental upside of gadolinium zirconate comes from its role in improving efficiency and reducing waste. By allowing engines and turbines to run hotter and more stably, GdZr₂O₇ coatings directly contribute to burning less fuel for the same output. The University of Virginia highlights that improving TBCs leads to “burning less fuel to generate the same amount of energy, resulting in… lower greenhouse gas emissions”. In simpler terms, every percentage point of efficiency gained can translate into tons of CO₂ saved over a machine’s life.

Consider an airliner: if its turbines operate 3–5% more efficiently, the fuel savings (and emission cuts) over thousands of flights are enormous. Likewise, power plants – even those burning natural gas – benefit because they can produce more electricity from each cubic meter of fuel. When electricity grids mix renewables with turbine backup, having high-efficiency turbines smooths peak demand with less added fossil fuel.

On the consumer side, anything that prolongs engine life or reduces maintenance also has an environmental effect. High-performance TBCs can extend the life of hot-section parts, meaning fewer replacements and less industrial waste. And from a sustainability standpoint, GdZr₂O₇ itself is chemically stable (it won’t corrode easily or release toxic vapors), and current production methods allow recycling of unused ceramic powders. (Of course, gadolinium is a rare earth, so responsible sourcing and recycling are important. But this is true for all high-tech materials, and many industries have supply-chain controls for rare-earths.)

Applications in Green Technologies

Next-Generation Jet and Aircraft Engines: Modern and future jet engines aim for ever-higher combustion temperatures to improve thrust-to-weight ratios and fuel economy. GdZr₂O₇’s high stability and low κ directly support this goal. For example, advanced military jets and proposed commercial supersonic aircraft could see performance gains from GdZr₂O₇ TBCs.

Industrial and Power Gas Turbines: Utilities use large gas turbines for peak power and for combined-cycle plants. GdZr₂O₇ coatings allow these turbines to extract more energy from each fuel input, meaning more megawatts with the same fuel or the same megawatts with less fuel. This efficiency uptick helps reduce CO₂ per MWh of electricity.

Aerospace (Spacecraft and Reentry Vehicles): Space shuttles and rockets experience blistering reentry and launch heat. While GdZr₂O₇ is not used on all these surfaces, it’s studied for use in hypersonic vehicle coatings and engine nozzles for the very high-temperature sections. Any improvement can reduce cooling needs or material stress.

Green Energy Systems: In solar thermal power plants, mirrors concentrate sunlight onto receivers that reach 1000+ °C. Coating these receivers with low-κ ceramics like GdZr₂O₇ could improve insulation, making solar-to-electric conversion slightly more efficient. Also, experimental thermoelectric generators (which convert heat directly to electricity) benefit if their hot side stays hotter.

In all these cases, the environmental impact comes from using less energy (fuel or power input) for the same job. Higher efficiency always means lower waste heat and thus fewer emissions for given output. As one materials scientist put it, better TBC materials like gadolinium zirconate are key to a “more sustainable energy future” by enabling turbines and engines to run cooler, last longer, and operate more efficiently.

Technical Highlights

Gadolinium zirconate’s combination of properties is unique. To summarize some standout facts:

Low κ, high melting point: Its melting point is ~2570 °C, but its useful temperature is limited by phase stability (~1500 °C). Even well below melting, it remains a superb insulator.

Crystal structure: It has a pyrochlore lattice (space group Fd3m) that becomes defective fluorite at high temperature. This ordered-to-disordered transition does not degrade performance until above ~1200–1500 °C.

Thermal expansion: GdZr₂O₇ has a higher thermal expansion coefficient than YSZ. This can be advantageous by better matching metal substrates and reducing crack risk on heating.

Mechanical properties: As a brittle ceramic, it’s not particularly tough – so coatings often use it in combination (e.g. thin GdZr₂O₇ top layer over a tougher base layer).

Manufacturing: GdZr₂O₇ TBCs can be applied by standard methods (atmospheric plasma spray, suspension plasma spray, EB-PVD). Suppliers like Epomaterial offer GdZr₂O₇ powder specifically designed for plasma spray.

These technical details are balanced by accessibility: while gadolinium and zirconium are “rare-earth” elements, the resulting oxide is chemically inert and safe to handle in normal industrial use. (Care is always taken to avoid inhalation of fine powders, but Gd₂Zr₂O₇ is no more hazardous than other oxide ceramics.)

Conclusion

Zirconate gadolinium (Gd₂Zr₂O₇) is a leading-edge ceramic material that combines high-temperature durability with exceptionally low thermal conductivity. These qualities make it ideal for advanced thermal barrier coatings in aerospace, power generation, and other high-heat applications. By enabling higher operating temperatures and improved engine efficiency, gadolinium zirconate contributes directly to energy savings and emission reductions – goals at the heart of sustainable technology. In the drive for greener engines and turbines, materials like GdZr₂O₇ play a crucial role: they allow us to push performance limits while trimming our environmental footprint.

For engineers and material scientists, gadolinium zirconate is worth watching. Its thermal conductivity (around 1–2 W/m·K at ~1000 °C) is among the lowest for any ceramic, yet it can withstand the extreme temperatures of next-generation turbines. Suppliers (including Epomaterial’s zirconate gadolinium (GZO) 99.9% product) are already providing this material for thermal spray coatings, indicating growing industrial use. As demand rises for cleaner aviation and power systems, gadolinium zirconate’s unique balance of properties – insulating heat while enduring it – is exactly what’s needed.

Sources: Peer-reviewed studies and industry publications on rare-earth pyrochlores and TBCs. (Epomaterial’s product listing for Gd₂Zr₂O₇ provides material specs.) These confirm the low thermal conductivity values and highlight the sustainability advantages of advanced TBC materials.

Post time: Jun-04-2025