In the vast lexicon of chemical compounds, some entries remain quietly indispensable, their influence woven into the very fabric of next-generation technology. They are the unseen enablers, the molecular architects that empower breakthroughs in fields from quantum computing to sustainable manufacturing. One such pivotal compound is Zirconium Acetylacetonate, identified by its CAS number 17501-44-9.

While its name might seem esoteric to those outside of specialized fields, its impact is becoming increasingly profound. This is not merely a chemical to be cataloged; it is a sophisticated tool, a high-purity precursor that is unlocking new paradigms in electronics, green chemistry, and nanotechnology. This article delves into the multifaceted world of Zirconium Acetylacetonate, exploring how its unique properties are addressing some of the most pressing technological and environmental challenges of our time.

Deconstructing the Molecule: The Foundations of Versatility

At its core, Zirconium Acetylacetonate (often abbreviated as Zr(acac)₄) is an organometallic coordination complex. This structure involves a central zirconium atom bonded to four acetylacetonate ligands, which form stable, six-membered chelate rings. This is not just a trivial structural detail; this chelation is the very source of the compound's remarkable utility.

The key attributes that stem from this molecular architecture include:

● Exceptional Thermal Stability: Zr(acac)₄ can withstand significant heat before decomposing. This remarkable stability is not merely a passive trait but an active enabler, allowing for a highly controlled, predictable thermal decomposition pathway that yields high-purity zirconium oxide (ZrO₂) films with minimal carbonaceous impurities.

● Superb Solubility: Its ability to dissolve readily in a range of organic solvents makes it exceptionally versatile for solution-based processing techniques. This solubility is crucial for creating uniform, defect-free coatings and materials through methods like sol-gel synthesis and spin-coating.

● High Volatility: The compound's capacity to transition into a gaseous state at relatively low temperatures makes it a quintessential precursor for vapor deposition techniques, where precision is paramount.

It is the synergistic interplay of these characteristics that elevates Zirconium Acetylacetonate from a mere laboratory chemical to a strategic material for industrial innovation.

Architecting the Future of Electronics: The High-κ Dielectric Revolution

The relentless march of the electronics industry, as once described by Moore's Law, is predicated on the miniaturization of components, most notably the transistor. As transistors shrink to nanoscopic dimensions, the problem of quantum tunneling and current leakage through the gate dielectric becomes a formidable barrier. The solution lies in replacing traditional silicon dioxide with materials that have a higher dielectric constant (high-κ).

This is where Zirconium Acetylacetonate takes center stage. It serves as a premier precursor for depositing ultra-thin films of zirconium oxide (ZrO₂), a celebrated high-κ dielectric. Through advanced deposition methods like Atomic Layer Deposition (ALD) and Chemical Vapor Deposition (CVD), a single, highly controlled layer of Zr(acac)₄ molecules can be introduced into a reaction chamber, decomposing perfectly to form a pristine ZrO₂ layer just atoms thick.

The implications are monumental:

● Next-Generation Transistors: These high-κ gate dielectrics enable the creation of smaller, faster, and more power-efficient transistors, pushing the boundaries of computational power.

● Advanced Memory Devices: Its utility extends to nonvolatile memory technologies, such as flash memory, where ZrO₂ films act as charge-trap layers, enhancing data retention and device longevity.

● Vibrant Quantum Dot LEDs (QLEDs): In the realm of advanced displays, Zr(acac)₄ is used to create conductive interlayer materials that significantly boost the efficiency, brightness, and operational lifetime of QLEDs, leading to more vivid and energy-saving screens.

Catalyzing a Greener Future: A Commitment to Sustainability

As global industries pivot towards sustainability and a circular economy, the demand for innovative "green chemistry" solutions has soared. Zirconium Acetylacetonate is emerging as a powerful catalyst in this transition, particularly in the domain of polymer science.

One of its most laudable applications is as an initiator in the ring-opening polymerization (ROP) of cyclic esters, such as lactide. This process is a cornerstone for producing biodegradable and biocompatible polymers like polylactic acid (PLA). By facilitating this reaction with high efficiency and control, Zr(acac)₄ contributes directly to the development of sustainable alternatives to petroleum-based plastics, finding use in applications from compostable packaging to advanced biomedical implants.

Furthermore, it functions as a potent cross-linking agent and hardening accelerator in various resin systems, including silicones and epoxies. By creating stronger, more resilient polymer networks, it enhances the durability and performance of materials, extending their service life and reducing waste. This catalytic prowess positions Zr(acac)₄ not just as a manufacturing component, but as an active participant in building a more sustainable material ecosystem.

The Nanoscale Frontier: Engineering with Atomic Precision

The field of nanotechnology, which operates at the scale of a billionth of a meter, requires precursors that offer absolute control over material formation. Zirconium Acetylacetonate excels in this arena, enabling the synthesis of highly structured zirconium-based nanomaterials.

Using sol-gel processes, where Zr(acac)₄ is a key ingredient, scientists can fabricate:

● Zirconia Nanoparticles: These tiny particles possess an enormous surface-area-to-volume ratio, making them highly effective in applications like photocatalysis, where they can be used to break down environmental pollutants under light.

● Zirconia Nanofibers: Produced via electrospinning techniques, these nanofibers can be woven into advanced membranes for high-temperature filtration or used to reinforce composite materials, imparting exceptional strength and thermal resistance.

The ability to meticulously control the size, shape, and crystallinity of these nanostructures is fundamental to their function, and this control begins with the quality of the molecular precursor.

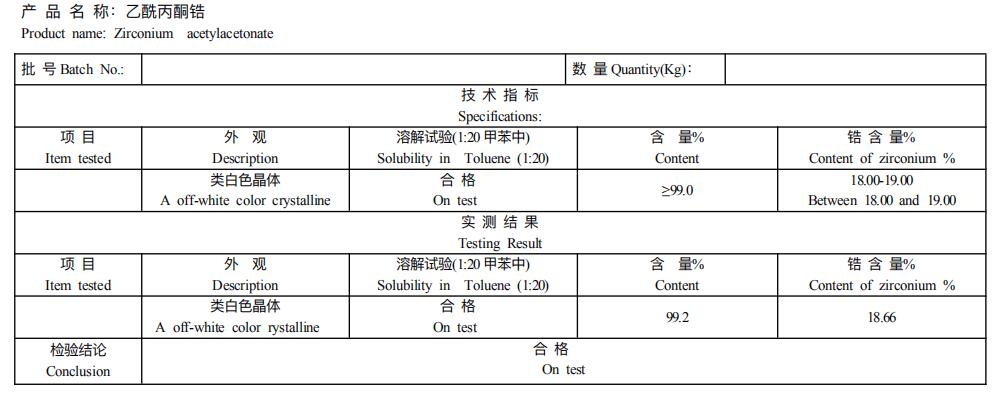

Epoch Material: Your Source for Foundational Purity

The successful realization of these advanced applications—from flawless semiconductor layers to efficient catalytic reactions—is predicated on the impeccable quality of the precursor material. Any impurity or inconsistency in the Zirconium Acetylacetonate can lead to critical defects, device failure, or unpredictable reaction kinetics. This is where precision matters most.

Epoch Material is committed to supplying the highest caliber of specialty chemicals required to drive these innovations forward. For researchers and manufacturers operating at the vanguard of technology, sourcing a premium, high-purity precursor is a foundational step toward achieving reproducible, high-performance results. We understand that the molecule is the starting point for monumental achievements.

To explore the technical specifications and secure a reliable supply for your groundbreaking work, we invite you to visit our product page: Zirconium Acetylacetonate (CAS 17501-44-9).

Conclusion: A Molecule of Infinite Potential

Zirconium Acetylacetonate is a compelling example of how a single, well-defined compound can have an outsized impact across disparate fields. It is a bridge connecting the esoteric world of coordination chemistry to the tangible technologies that define our modern era. From the smartphone in your pocket to the sustainable materials of the future, its influence is subtle but essential. As research continues to uncover new catalytic pathways and material applications, the role of this versatile molecular architect is set to expand even further, solidifying its status as a cornerstone of 21st-century innovation.

Post time: Jun-20-2025