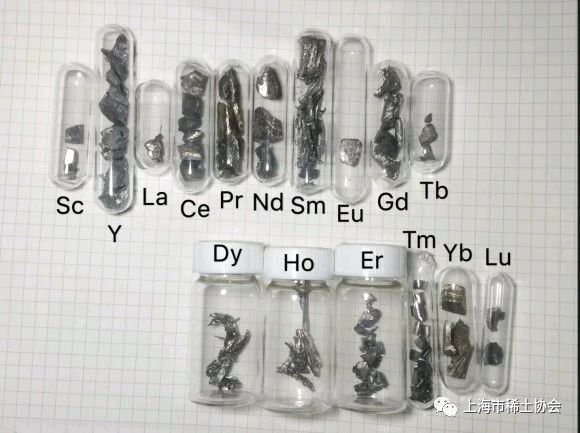

Application of Rare Earth in Composite Materials

Rare earth elements have unique 4f electronic structure, large atomic magnetic moment, strong spin coupling and other characteristics. When forming complexes with other elements, their coordination number can vary from 6 to 12. Rare earth compounds have a variety of crystal structures. The special physical and chemical properties of rare earths make them widely used in the smelting of high-quality steel and non-ferrous metals, special glass and high-performance ceramics, permanent magnet materials, hydrogen storage materials, luminescent and laser materials, nuclear materials, and other fields. With the continuous development of composite materials, the application of rare earths has also expanded to the field of composite materials, attracting widespread attention in improving the interface properties between heterogeneous materials.

The main application forms of rare earth in the preparation of composite materials include: ① adding rare earth metals to composite materials; ② Add in the form of rare earth oxides to the composite material; ③ Polymers doped or bonded with rare earth metals in polymers are used as matrix materials in composite materials. Among the above three forms of rare earth application, the first two forms are mostly added to metal matrix composite, while the third is mainly applied to polymer matrix composites, and the ceramic matrix composite are mainly added in the second form.

Rare earth mainly acts on metal matrix and ceramic matrix composite in the form of additives, stabilizers, and sintering additives, greatly improving their performance, reducing production costs, and making its industrial application possible.

The addition of rare earth elements as additives in composite materials mainly plays a role in improving the interface performance of composite materials and promoting the refinement of metal matrix grains. The mechanism of action is as follows.

① Improve the wettability between the metal matrix and the reinforcing phase. The electronegativity of rare earth elements is relatively low (the smaller the electronegativity of metals, the more active the electronegativity of nonmetals). For example, La is 1.1, Ce is 1.12, and Y is 1.22. The electronegativity of common base metal Fe is 1.83, Ni is 1.91, and Al is 1.61. Therefore, rare earth elements will preferentially adsorb on the grain boundaries of the metal matrix and reinforcement phase during the smelting process, reducing their interface energy, increasing the adhesion work of the interface, reducing the wetting angle, and thereby improving the wettability between the matrix and reinforcement phase. Research has shown that the addition of La element to the aluminum matrix effectively improves the wettability of AlO and aluminum liquid, and improves the microstructure of composite materials.

② Promote the refinement of metal matrix grains. The solubility of rare earth in metal crystal is small, because the atomic radius of rare earth elements is large, and the atomic radius of metal matrix is relatively small. The entry of rare earth elements with larger radius into the matrix lattice will cause lattice distortion, which will increase the system energy. To maintain the lowest free energy, rare earth atoms can only enrich towards irregular grain boundaries, which to some extent hinders the free growth of matrix grains. At the same time, the enriched rare earth elements will also adsorb other alloy elements, increasing the concentration gradient of alloy elements, causing local component undercooling, and enhancing the heterogeneous nucleation effect of the liquid metal matrix. In addition, the undercooling caused by elemental segregation can also promote the formation of segregated compounds and become effective heterogeneous nucleation particles, thereby promoting the refinement of the metal matrix grains.

③ Purify grain boundaries. Due to the strong affinity between rare earth elements and elements such as O, S, P, N, etc., the standard free energy of formation for oxides, sulfides, phosphides, and nitrides is low. These compounds have a high melting point and low density, some of which can be removed by floating up from the alloy liquid, while others are evenly distributed within the grain, reducing the segregation of impurities at the grain boundary, thereby purifying the grain boundary and improving its strength.

It should be noted that, due to the high activity and low melting point of rare earth metals, when they are added to metal matrix composite, their contact with oxygen needs to be specially controlled during the addition process.

A large number of practices have proved that adding rare earth oxides as stabilizers, sintering aids, and doping modifiers to different metal matrix and ceramic matrix composite can greatly improve the strength and toughness of materials, reduce their sintering temperature, and thus reduce production costs. The main mechanism of its action is as follows.

① As a sintering additive, it can promote sintering and reduce porosity in composite materials. The addition of sintering additives is to generate a liquid phase at high temperatures, reduce the sintering temperature of composite materials, inhibit the high-temperature decomposition of materials during the sintering process, and obtain dense composite materials through liquid phase sintering. Due to the high stability, weak high-temperature volatility, and high melting and boiling points of rare earth oxides, they can form glass phases with other raw materials and promote sintering, making them an effective additive. At the same time, the rare earth oxide can also form solid solution with the ceramic matrix, which can generate crystal defects inside, activate the lattice and promote sintering.

② Improve microstructure and refine grain size. Due to the fact that the added rare earth oxides mainly exist at the grain boundaries of the matrix, and due to their large volume, rare earth oxides have high migration resistance in the structure, and also hinder the migration of other ions, thereby reducing the migration rate of grain boundaries, inhibiting grain growth, and hindering the abnormal growth of grains during high-temperature sintering. They can obtain small and uniform grains, which is conducive to the formation of dense structures; On the other hand, by doping rare earth oxides, they enter the grain boundary glass phase, improving the strength of the glass phase and thus achieving the goal of improving the mechanical properties of the material.

Rare earth elements in polymer matrix composites mainly affect them by improving the properties of the polymer matrix. Rare earth oxides can increase the thermal decomposition temperature of polymers, while rare earth carboxylates can improve the thermal stability of polyvinyl chloride. Doping polystyrene with rare earth compounds can improve the stability of polystyrene and significantly increase its impact strength and bending strength.

Post time: Apr-26-2023