In recent years, the words “rare earth elements“, “new energy vehicles”, and “integrated development” have been appearing more and more frequently in the media. Why? This is mainly due to the increasing attention paid by the country to the development of environmental protection and energy-saving industries, and the enormous potential for the integration and development of rare earth elements in the field of new energy vehicles. What are the four major application directions of rare earth elements in new energy vehicles?

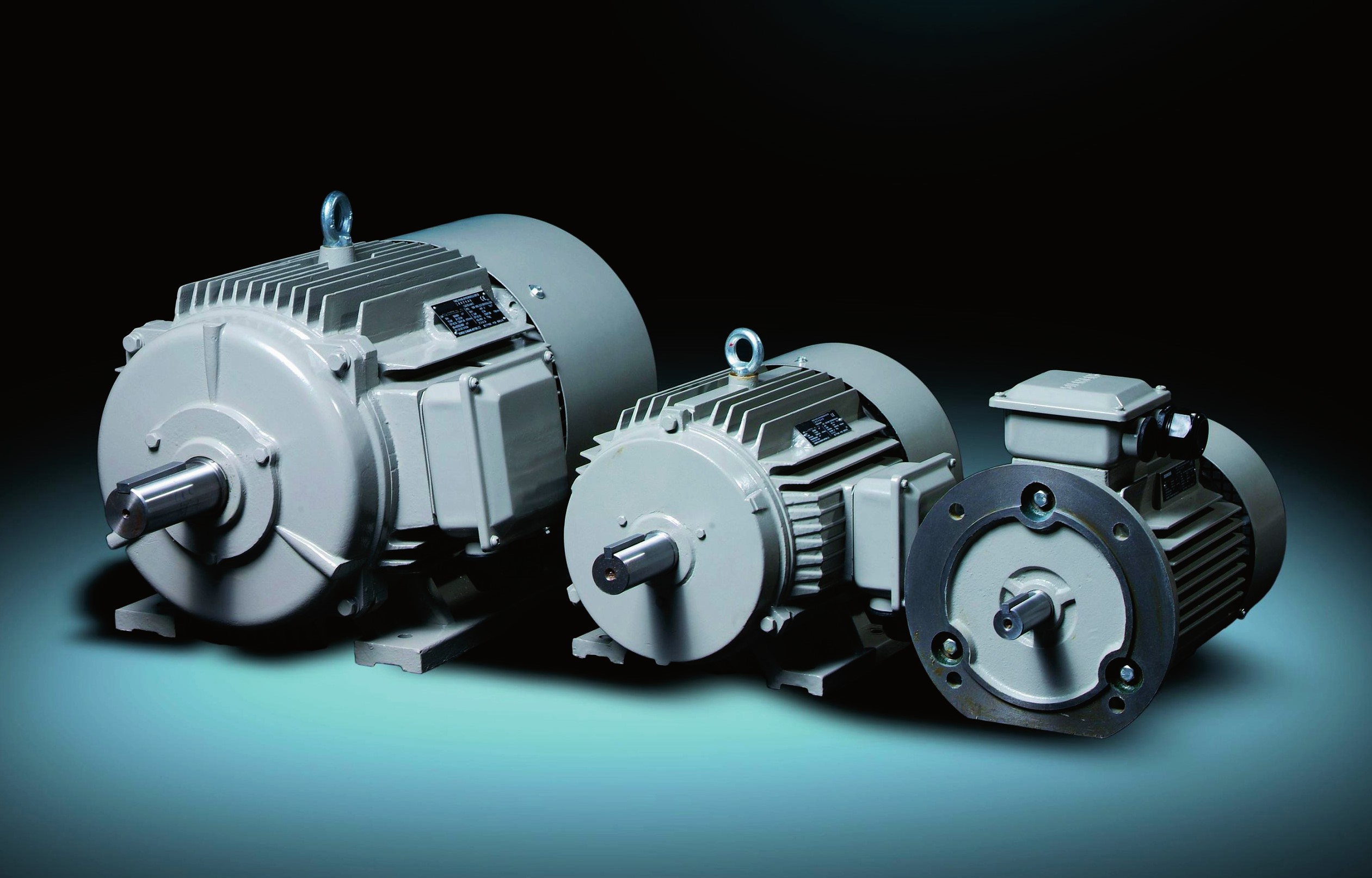

△ Rare earth permanent magnet motor

I

Rare earth permanent magnet motor

Rare earth permanent magnet motor is a new type of permanent magnet motor that emerged in the early 1970s. Its working principle is the same as that of an electrically excited synchronous motor, except that the former uses a permanent magnet to replace the excitation winding for excitation. Compared with traditional electric excitation motors, rare earth permanent magnet motors have significant advantages such as simple structure, reliable operation, small size, light weight, low losses, and high efficiency. Moreover, the shape and size of the motor can be flexibly designed, which makes it highly valued in the field of new energy vehicles. Rare earth permanent magnet motors in automobiles mainly convert the electrical energy of the power battery into mechanical energy, driving the engine flywheel to rotate and start the engine.

II

Rare earth power battery

Rare earth elements can not only participate in the preparation of current mainstream electrode materials for lithium batteries, but also serve as raw materials for the preparation of positive electrodes for Lead–acid battery or Nickel–metal hydride battery.

Lithium battery: Due to the addition of rare earth elements, the structural stability of the material is greatly guaranteed, and the three-dimensional channels for active lithium ion migration are also expanded to a certain extent. This enables the prepared lithium-ion battery to have higher charging stability, electrochemical cycling reversibility, and longer cycle life.

Lead acid battery: domestic research shows that the addition of rare earth is conducive to improving the tensile strength, hardness, corrosion resistance and oxygen evolution Overpotential of lead based alloy of electrode plate. The addition of rare earth in the active component can reduce the release of positive oxygen, improve the utilization rate of positive active material, and thus improve the performance and service life of the battery.

Nickel–metal hydride battery: Nickel–metal hydride battery has the advantages of high specific capacity, high current, good charge discharge performance, and no pollution, so it is called “green battery” and widely used in automobile, electronics and other fields. In order to keep the excellent high-speed discharge characteristics of Nickel–metal hydride battery while inhibiting the decay of its life, Japanese patent JP2004127549 introduces that the battery cathode can be composed of rare earth magnesium nickel based hydrogen storage alloy.

△ New energy vehicles

III

Catalysts in ternary catalytic converters

As is well known, not all new energy vehicles can achieve zero emissions, such as hybrid electric vehicles and programmable electric vehicles, which release a certain amount of toxic substances during use. In order to reduce the emissions of their automobile exhaust, some vehicles are forced to install three-way catalytic converters when leaving the factory. When the high-temperature automobile exhaust passes through, the three-way catalytic converters will enhance the activity of CO, HC and NOx in Go through the built-in purification agent, so that they can complete Redox and generate harmless gases, which is conducive to environmental protection.

The main component of the ternary catalyst is rare earth elements, which play a key role in storing materials, replacing some of the main catalysts, and serving as catalytic aids. The rare earth used in the tail gas purification catalyst is mainly a mixture of cerium oxide, praseodymium oxide and Lanthanum oxide, which are rich in rare earth minerals in China.

IV

Ceramic Materials in Oxygen Sensors

Rare earth elements have unique oxygen storage functions due to their unique electronic structure, and are often used in the preparation of ceramic materials for oxygen sensors in electronic fuel injection systems, resulting in better catalytic performance. The electronic fuel injection system is an advanced fuel injection device adopted by gasoline engines without carburetors, mainly composed of three major parts: air system, fuel system, and control system.

In addition to this, rare earth elements also have a wide range of applications in parts such as gears, tires, and body steel. It can be said that rare earths are essential elements in the field of new energy vehicles.

Post time: Jul-14-2023