Ytterbium: atomic number 70, atomic weight 173.04, element name derived from its discovery location. The content of ytterbium in the crust is 0.000266%, mainly present in phosphorite and black rare gold deposits, while the content in monazite is 0.03%, with 7 natural isotopes.

Discovering History

Discovered by: Marinak

Time: 1878

Location: Switzerland

In 1878, Swiss chemists Jean Charles and G Marignac discovered a new rare earth element in “erbium”. In 1907, Ulban and Weils pointed out that Marignac separated a mixture of lutetium oxide and ytterbium oxide. In memory of the small village named Yteerby near Stockholm, where yttrium ore was discovered, this new element was named Ytterbium with the symbol Yb.

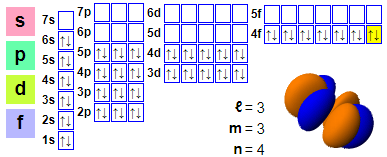

Electron configuration

1s2 2s2 2p6 3s2 3p6 4s2 3d10 4p6 5s2 4d10 5p6 6s2 4f14

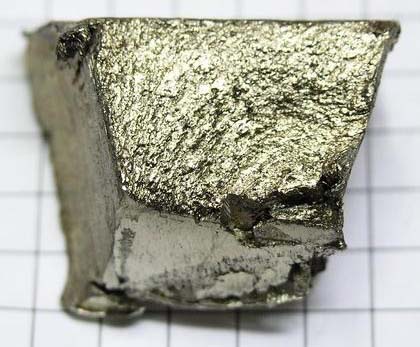

Metal

Metallic ytterbium is silver gray, ductile, and has a soft texture. At room temperature, ytterbium can be slowly oxidized by air and water.

There are two crystal structures: α- The type is a face centered cubic crystal system (room temperature -798 ℃); β- The type is a body centered cubic (above 798 ℃) lattice. Melting point 824 ℃, boiling point 1427 ℃, relative density 6.977( α- Type), 6.54( β- Type).

Insoluble in cold water, soluble in acids and liquid ammonia. It is quite stable in the air. Similar to samarium and europium, ytterbium belongs to the variable valence rare earth, and can also be in a positive divalent state in addition to being usually trivalent.

Due to this variable valence characteristic, the preparation of metallic ytterbium should not be carried out by electrolysis, but by reduction distillation method for preparation and purification. Usually, lanthanum metal is used as a reducing agent for reduction distillation, utilizing the difference between the high vapor pressure of ytterbium metal and the low vapor pressure of lanthanum metal. Alternatively, thulium, ytterbium, and lutetium concentrates can be used as raw materials, and metal lanthanum can be used as a reducing agent. Under high temperature vacuum conditions of>1100 ℃ and<0.133Pa, metal ytterbium can be directly extracted by reduction distillation. Like samarium and europium, ytterbium can also be separated and purified through wet reduction. Usually, thulium, ytterbium, and lutetium concentrates are used as raw materials. After dissolution, ytterbium is reduced to a divalent state, causing significant differences in properties, and then separated from other trivalent rare earths. The production of high-purity ytterbium oxide is usually carried out by extraction chromatography or ion exchange method

Application

Used for manufacturing special alloys. Ytterbium alloys have been applied in dental medicine for metallurgical and chemical experiments.

In recent years, ytterbium has emerged and rapidly developed in the fields of fiber optic communication and laser technology.

With the construction and development of the “information highway”, computer networks and long-distance optical fiber transmission systems have increasingly high requirements for the performance of optical fiber materials used in optical communication. Ytterbium ions, due to their excellent spectral properties, can be used as fiber amplification materials for optical communication, just like erbium and thulium. Although rare earth element erbium is still the main player in the preparation of fiber amplifiers, traditional erbium-doped quartz fibers have a small gain bandwidth (30nm), making it difficult to meet the requirements of high-speed and high-capacity information transmission. Yb3+ions have a much larger absorption cross-section than Er3+ions around 980nm. Through the sensitization effect of Yb3+and the energy transfer of erbium and ytterbium, the 1530nm light can be greatly enhanced, thereby greatly improving the amplification efficiency of the light.

In recent years, erbium ytterbium co doped phosphate glass has been increasingly favored by researchers. Phosphate and fluorophosphate glasses have good chemical and thermal stability, as well as wide infrared transmittance and large non-uniform broadening characteristics, making them ideal materials for broadband and high gain erbium-doped amplification fiber glass. Yb3+doped fiber amplifiers can achieve power amplification and small signal amplification, making them suitable for fields such as fiber optic sensors, free space laser communication, and ultra short pulse amplification. China has currently built the world’s largest single channel capacity and fastest speed optical transmission system, and has the widest information highway in the world. Ytterbium doped and other rare earth doped fiber amplifiers and laser materials play a crucial and significant role in them.

The spectral characteristics of ytterbium are also used as high-quality laser materials, both as laser crystals, laser glasses, and fiber lasers. As a high-power laser material, ytterbium doped laser crystals have formed a huge series, including ytterbium doped yttrium aluminum garnet (Yb: YAG), ytterbium doped gadolinium gallium garnet (Yb: GGG), ytterbium doped calcium fluorophosphate (Yb: FAP), ytterbium doped strontium fluorophosphate (Yb: S-FAP), ytterbium doped yttrium vanadate (Yb: YV04), ytterbium doped borate, and silicate. Semiconductor laser (LD) is a new type of pump source for solid-state lasers. Yb: YAG has many characteristics suitable for high-power LD pumping and has become a laser material for high-power LD pumping. Yb: S-FAP crystal may be used as a laser material for laser nuclear fusion in the future, which has attracted people’s attention. In tunable laser crystals, there is chromium ytterbium holmium yttrium aluminum gallium garnet (Cr, Yb, Ho: YAGG) with wavelengths ranging from 2.84 to 3.05 μ Continuously adjustable between m. According to statistics, most of the infrared warheads used in missiles around the world use 3-5 μ Therefore, the development of Cr, Yb, Ho: YSGG lasers can provide effective interference for mid infrared guided weapon countermeasures, and has important military significance. China has achieved a series of innovative results with international advanced level in the field of ytterbium doped laser crystals (Yb: YAG, Yb: FAP, Yb: SFAP, etc.), solving key technologies such as crystal growth and laser fast, pulse, continuous, and adjustable output. The research results have been applied in national defense, industry, and scientific engineering, and ytterbium doped crystal products have been exported to multiple countries and regions such as the United States and Japan.

Another major category of ytterbium laser materials is laser glass. Various high emission cross-section laser glasses have been developed, including germanium tellurite, silicon niobate, borate, and phosphate. Due to the ease of glass molding, it can be made into large sizes and has characteristics such as high light transmittance and high uniformity, making it possible to produce high-power lasers. The familiar rare earth laser glass used to be mainly neodymium glass, which has a development history of over 40 years and mature production and application technology. It has always been the preferred material for high-power laser devices and has been used in nuclear fusion experimental devices and laser weapons. The high-power laser devices built in China, consisting of laser neodymium glass as the main laser medium, have reached the world’s advanced level. But laser neodymium glass now faces a powerful challenge from laser ytterbium glass.

In recent years, a large number of studies have shown that many properties of laser ytterbium glass exceed those of neodymium glass. Due to the fact that ytterbium doped luminescence only has two energy levels, the energy storage efficiency is high. At the same gain, ytterbium glass has an energy storage efficiency 16 times higher than neodymium glass, and a fluorescence lifetime 3 times that of neodymium glass. It also has advantages such as high doping concentration, absorption bandwidth, and can be directly pumped by semiconductors, making it very suitable for high-power lasers. However, the practical application of ytterbium laser glass often relies on the assistance of neodymium, such as using Nd3+as a sensitizer to make ytterbium laser glass operate at room temperature and μ Laser emission is achieved at m wavelength. So, ytterbium and neodymium are both competitors and collaborative partners in the field of laser glass.

By adjusting the glass composition, many luminescent properties of ytterbium laser glass can be improved. With the development of high-power lasers as the main direction, lasers made of ytterbium laser glass are increasingly widely used in modern industry, agriculture, medicine, scientific research, and military applications.

Military use: Using the energy generated by nuclear fusion as energy has always been an expected goal, and achieving controlled nuclear fusion will be an important means for humanity to solve energy problems. Ytterbium doped laser glass is becoming the preferred material for achieving inertial confinement fusion (ICF) upgrades in the 21st century due to its excellent laser performance.

Laser weapons use the enormous energy of a laser beam to strike and destroy targets, generating temperatures of billions of degrees Celsius and directly attacking at the speed of light. They can be referred to as Nadana and have great lethality, especially suitable for modern air defense weapon systems in warfare. The excellent performance of ytterbium doped laser glass has made it an important basic material for manufacturing high-power and high-performance laser weapons.

Fiber laser is a rapidly developing new technology and also belongs to the field of laser glass applications. Fiber laser is a laser that uses fiber as the laser medium, which is a product of the combination of fiber and laser technology. It is a new laser technology developed on the basis of erbium doped fiber amplifier (EDFA) technology. A fiber laser is composed of a semiconductor laser diode as the pump source, a fiber optic waveguide and a gain medium, and optical components such as grating fibers and couplers. It does not require mechanical adjustment of the optical path, and the mechanism is compact and easy to integrate. Compared with traditional solid-state lasers and semiconductor lasers, it has technological and performance advantages such as high beam quality, good stability, strong resistance to environmental interference, no adjustment, no maintenance, and compact structure. Due to the fact that the doped ions are mainly Nd+3, Yb+3, Er+3, Tm+3, Ho+3, all of which use rare earth fibers as gain media, the fiber laser developed by the company can also be called a rare earth fiber laser.

Laser application: High power ytterbium doped double clad fiber laser has become a hot field in solid-state laser technology internationally in recent years. It has the advantages of good beam quality, compact structure, and high conversion efficiency, and has broad application prospects in industrial processing and other fields. Double clad ytterbium doped fibers are suitable for semiconductor laser pumping, with high coupling efficiency and high laser output power, and are the main development direction of ytterbium doped fibers. China’s double clad ytterbium doped fiber technology is no longer on par with the advanced level of foreign countries. The ytterbium doped fiber, double clad ytterbium doped fiber, and erbium ytterbium co doped fiber developed in China have reached the advanced level of similar foreign products in terms of performance and reliability, have cost advantages, and have core patented technologies for multiple products and methods.

The world-renowned German IPG laser company recently announced that their newly launched ytterbium doped fiber laser system has excellent beam characteristics, a pump life of over 50000 hours, a central emission wavelength of 1070nm-1080nm, and an output power of up to 20KW. It has been applied in fine welding, cutting, and rock drilling.

Laser materials are the core and foundation for the development of laser technology. There has always been a saying in the laser industry that ‘one generation of materials, one generation of devices’. To develop advanced and practical laser devices, it is necessary to first possess high-performance laser materials and integrate other relevant technologies. Ytterbium doped laser crystals and laser glass, as the new force of solid laser materials, are promoting the innovative development of fiber optic communication and laser technology, especially in cutting-edge laser technologies such as high-power nuclear fusion lasers, high-energy beat tile lasers, and high-energy weapon lasers.

In addition, ytterbium is also used as a fluorescent powder activator, radio ceramics, additives for electronic computer memory components (magnetic bubbles), and optical glass additives. It should be pointed out that yttrium and yttrium are both rare earth elements. Although there are significant differences in English names and element symbols, the Chinese phonetic alphabet has the same syllables. In some Chinese translations, yttrium is sometimes mistakenly referred to as yttrium. In this case, we need to trace the original text and combine element symbols to confirm.

Post time: Sep-13-2023