According to BusinessKorea, Hyundai Motor Group has started developing electric vehicle motors that do not heavily rely on Chinese “rare earth elements“.

According to industry insiders on August 13th, Hyundai Motor Group is currently developing a propulsion motor that does not use rare earth elements such as neodymium, dysprosium, and terbium at its Nanyang Research Center in Huacheng, Gyeonggi do. An industry insider said, “Hyundai Motor Group is developing a ‘wound rotor synchronous motor (WRSM)’ that completely avoids the use of permanent magnets containing rare earth elements

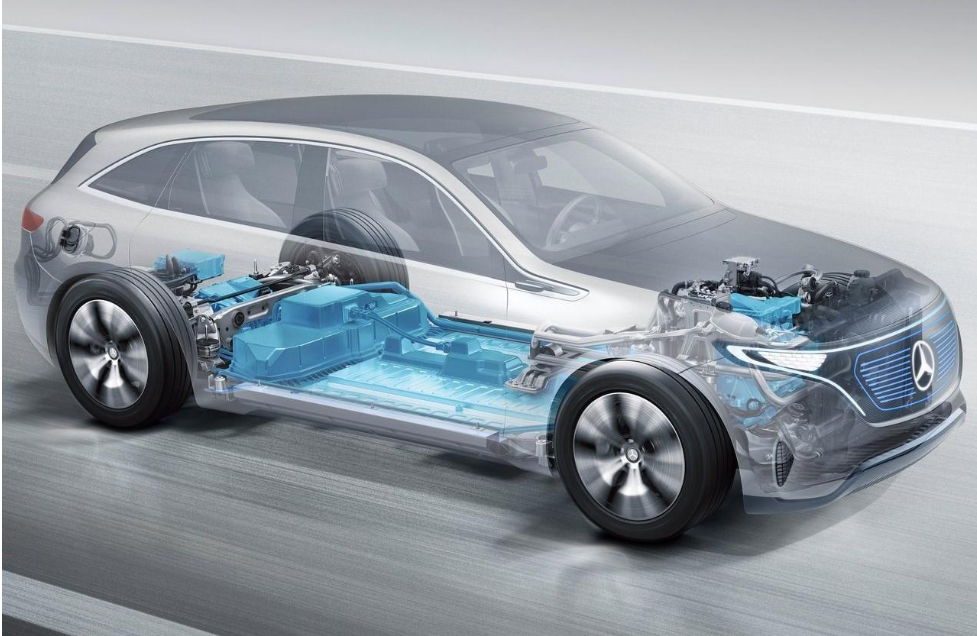

Neodymium is a substance with strong magnetism. When mixed with trace amounts of dysprosium and terbium, it can maintain magnetism even at temperatures up to 200 degrees Celsius. In the automotive industry, vehicle manufacturers use these neodymium based permanent magnets in their propulsion motors, often referred to as the “heart of electric vehicles”. In this setting, neodymium based permanent magnets are placed in the rotor (the rotating part of the motor), while coils made of winding are placed around the rotor to drive the motor using a “Permanent Magnet Synchronous Motor (PMSM)” configuration.

On the other hand, the new motor being developed by Hyundai Motor Group uses electromagnets instead of permanent magnets in the rotor. This makes it a motor that does not rely on rare earth elements such as neodymium, dysprosium, and terbium.

The reason why Hyundai Motor Group has shifted to developing electric vehicle motors that do not contain rare earth elements is due to the recent significant increase in China’s rare earth imports. China accounts for 58% of the world’s neodymium mining output and 90% of the world’s refined neodymium. According to the Korea Trade Association, with the increase in production of electric vehicles by domestic Korean automakers, the import value of permanent magnets mainly composed of rare earth elements has increased from 239 million US dollars (approximately 318 billion Korean won) in 2020 to 641 million US dollars in 2022, an increase of nearly 2.7 times. About 87.9% of the imported permanent magnets from South Korea come from China.

According to the report, the Chinese government is considering using the “rare earth magnet export ban” as a countermeasures against US semiconductor export restrictions. If China implements export restrictions, it will directly hit the whole vehicle manufacturers who actively promote the widespread transformation of electric vehicles.

In this situation, BMW and Tesla are also seeking to develop motors that do not contain rare earth elements. BMW has adopted the WRSM technology being developed by Hyundai Motor Group in the BMW i4 electric vehicle. However, compared to motors using rare earth magnets, existing WRSM motors have a shorter lifespan and higher energy or copper losses, resulting in lower efficiency. How Hyundai Motor Group solves this problem may be a key factor in achieving rare earth free automotive technology.

Tesla is currently developing a motor using ferrite permanent magnets, which are made by mixing metal elements with iron oxide. Ferrite permanent magnets are considered as substitutes for neodymium based permanent magnets. However, their magnetism is weak and not suitable for use in electric vehicle motors, which has led to some criticism in the industry.

Post time: Aug-15-2023