Terbium belongs to the category of heavy rare earths, with a low abundance in the Earth’s crust at only 1.1 ppm. Terbium oxide accounts for less than 0.01% of the total rare earths. Even in the high yttrium ion type heavy rare earth ore with the highest content of terbium, the terbium content only accounts for 1.1-1.2% of the total rare earth, indicating that it belongs to the “noble” category of rare earth elements. For over 100 years since the discovery of terbium in 1843, its scarcity and value have prevented its practical application for a long time. It is only in the past 30 years that terbium has shown its unique talent。

Swedish chemist Carl Gustaf Mosander discovered terbium in 1843. He found its impurities in Yttrium(III) oxide and Y2O3. Yttrium is named after the village of Ytterby in Sweden. Before the emergence of ion exchange technology, terbium was not isolated in its pure form.

Mosant first divided Yttrium(III) oxide into three parts, all named after ores: Yttrium(III) oxide, Erbium(III) oxide, and terbium oxide. Terbium oxide was originally composed of a pink part, due to the element now known as erbium. “Erbium(III) oxide” (including what we now call terbium) was originally the essentially colorless part in the solution. The insoluble oxide of this element is considered brown.

Later workers could hardly observe the tiny colorless “Erbium(III) oxide”, but the soluble pink part could not be ignored. Debates about the existence of Erbium(III) oxide have arisen repeatedly. In the chaos, the original name was reversed and the exchange of names was stuck, so the pink part was eventually mentioned as a solution containing erbium (in the solution, it was pink). It is now believed that workers who use sodium bisulfate or Potassium sulfate take Cerium(IV) oxide out of Yttrium(III) oxide and unintentionally turn terbium into a sediment containing cerium. Only about 1% of the original Yttrium(III) oxide, now known as “terbium”, is enough to pass a yellowish color to Yttrium(III) oxide. Therefore, terbium is a secondary component that initially contained it, and it is controlled by its immediate neighbors, gadolinium and dysprosium.

Afterwards, whenever other rare earth elements were separated from this mixture, regardless of the proportion of the oxide, the name of terbium was retained until finally, the brown oxide of terbium was obtained in pure form. Researchers in the 19th century did not use ultraviolet fluorescence technology to observe bright yellow or green nodules (III), making it easier for terbium to be recognized in solid mixtures or solutions.

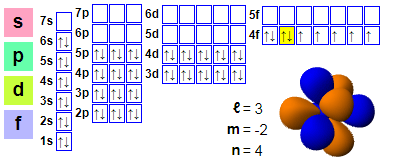

Electron configuration

Electron configuration:

1s2 2s2 2p6 3s2 3p6 4s2 3d10 4p6 5s2 4d10 5p6 6s2 4f9

The Electron configuration of terbium is [Xe] 6s24f9. Normally, only three electrons can be removed before the nuclear charge becomes too large to be further ionized, but in the case of terbium, semi filled terbium allows the fourth electron to be further ionized in the presence of very strong oxidants such as fluorine gas.

Terbium is a silver white rare earth metal with ductility, toughness, and softness that can be cut with a knife. Melting point 1360 ℃, boiling point 3123 ℃, density 8229 4kg/m3. Compared with the early Lanthanide, it is relatively stable in the air. As the ninth element of Lanthanide, terbium is a metal with strong electricity. It reacts with water to form hydrogen.

In nature, terbium has never been found to be a free element, a small amount of which exists in phosphocerium thorium sand and Gadolinite. Terbium coexists with other rare earth elements in monazite sand, with a generally 0.03% terbium content. Other sources are Xenotime and black rare gold ores, both of which are mixtures of oxides and contain up to 1% terbium.

Application

The application of terbium mostly involves high-tech fields, which are technology intensive and knowledge intensive cutting-edge projects, as well as projects with significant economic benefits, with attractive development prospects.

The main application areas include:

(1) Utilized in the form of mixed rare earths. For example, it is used as a rare earth compound fertilizer and feed additive for agriculture.

(2) Activator for green powder in three primary fluorescent powders. Modern optoelectronic materials require the use of three basic colors of phosphors, namely red, green, and blue, which can be used to synthesize various colors. And terbium is an indispensable component in many high-quality green fluorescent powders.

(3) Used as a magneto optical storage material. Amorphous metal terbium transition metal alloy thin films have been used to manufacture high-performance magneto-optical discs.

(4) Manufacturing magneto optical glass. Faraday rotatory glass containing terbium is a key material for manufacturing rotators, isolators, and circulators in laser technology.

(5) The development and development of terbium dysprosium ferromagnetostrictive alloy (TerFenol) has opened up new applications for terbium.

For agriculture and animal husbandry

Rare earth terbium can improve the quality of crops and increase the rate of photosynthesis within a certain concentration range. Terbium complexes have high biological activity. Ternary complexes of terbium, Tb (Ala) 3BenIm (ClO4) 3 · 3H2O, have good antibacterial and bactericidal effects on Staphylococcus aureus, Bacillus subtilis and Escherichia coli. They have broad antibacterial spectrum. The study of such complexes provides a new research direction for modern bactericidal drugs.

Used in the field of luminescence

Modern optoelectronic materials require the use of three basic colors of phosphors, namely red, green, and blue, which can be used to synthesize various colors. And terbium is an indispensable component in many high-quality green fluorescent powders. If the birth of rare earth color TV red fluorescent powder has stimulated the demand for yttrium and europium, then the application and development of terbium have been promoted by rare earth three primary color green fluorescent powder for lamps. In the early 1980s, Philips invented the world’s first compact energy-saving fluorescent lamp and quickly promoted it globally. Tb3+ions can emit green light with a wavelength of 545nm, and almost all the rare earth green phosphors use terbium as an activator.

The green phosphor for color TV cathode ray tube (CRT) has always been based on Zinc sulfide, which is cheap and efficient, but the terbium powder has always been used as the green phosphor for projection color TV, including Y2SiO5 ∶ Tb3+, Y3 (Al, Ga) 5O12 ∶ Tb3+and LaOBr ∶ Tb3+. With the development of large screen high-definition television (HDTV), high-performance green fluorescent powders for CRTs are also being developed. For example, a hybrid green fluorescent powder has been developed abroad, consisting of Y3 (Al, Ga) 5O12: Tb3+, LaOCl: Tb3+, and Y2SiO5: Tb3+, which have excellent luminescence efficiency at high current density.

The traditional X-ray fluorescent powder is calcium tungstate. In the 1970s and 1980s, rare earth phosphors for intensifying screens were developed, such as terbium activated sulfur Lanthanum oxide, terbium activated bromine Lanthanum oxide (for green screens), terbium activated sulfur Yttrium(III) oxide, etc. Compared with calcium tungstate, rare earth fluorescent powder can reduce the time of X-ray irradiation for patients by 80%, improve the resolution of X-ray films, extend the lifespan of X-ray tubes, and reduce energy consumption. Terbium is also used as a fluorescent powder activator for medical X-ray enhancement screens, which can greatly improve the sensitivity of X-ray conversion into optical images, improve the clarity of X-ray films, and greatly reduce the exposure dose of X-rays to the human body (by more than 50%).

Terbium is also used as an activator in the white LED phosphor excited by blue light for new semiconductor lighting. It can be used to produce terbium aluminum magneto optical crystal phosphors, using blue light emitting diodes as excitation light sources, and the generated fluorescence is mixed with the excitation light to produce pure white light.

The electroluminescent materials made of terbium mainly include Zinc sulfide green phosphor with terbium as the activator. Under ultraviolet irradiation, organic complexes of terbium can emit strong green fluorescence and can be used as thin film electroluminescent materials. Although significant progress has been made in the study of rare earth organic complex electroluminescent thin films, there is still a certain gap from practicality, and research on rare earth organic complex electroluminescent thin films and devices is still in depth.

The fluorescence characteristics of terbium are also used as fluorescence probes. For example, Ofloxacin terbium (Tb3+) fluorescence probe was used to study the interaction between Ofloxacin terbium (Tb3+) complex and DNA (DNA) by fluorescence spectrum and absorption spectrum, indicating that Ofloxacin Tb3+probe can form a groove binding with DNA molecules, and DNA can significantly enhance the fluorescence of Ofloxacin Tb3+system. Based on this change, DNA can be determined.

For magneto optical materials

Materials with Faraday effect, also known as magneto-optical materials, are widely used in lasers and other optical devices. There are two common types of magneto optical materials: magneto optical crystals and magneto optical glass. Among them, magneto-optical crystals (such as Yttrium iron garnet and terbium gallium garnet) have the advantages of adjustable operating frequency and high thermal stability, but they are expensive and difficult to manufacture. In addition, many magneto-optical crystals with high Faraday rotation angle have high absorption in the short wave range, which limits their use. Compared with magneto optical crystals, magneto optical glass has the advantage of high transmittance and is easy to be made into large blocks or fibers. At present, magneto-optical glasses with high Faraday effect are mainly rare earth ion doped glasses.

Used for magneto optical storage materials

In recent years, with the rapid development of multimedia and office automation, the demand for new high-capacity magnetic discs has been increasing. Amorphous metal terbium transition metal alloy films have been used to manufacture high-performance magneto-optical discs. Among them, the TbFeCo alloy thin film has the best performance. Terbium based magneto-optical materials have been produced on a large scale, and magneto-optical discs made from them are used as computer storage components, with storage capacity increased by 10-15 times. They have the advantages of large capacity and fast access speed, and can be wiped and coated tens of thousands of times when used for high-density optical discs. They are important materials in electronic information storage technology. The most commonly used magneto-optical material in the visible and near-infrared bands is Terbium Gallium Garnet (TGG) single crystal, which is the best magneto-optical material for making Faraday rotators and isolators.

For magneto optical glass

Faraday magneto optical glass has good transparency and isotropy in the visible and infrared regions, and can form various complex shapes. It is easy to produce large-sized products and can be drawn into optical fibers. Therefore, it has broad application prospects in magneto optical devices such as magneto optical isolators, magneto optical modulators, and fiber optic current sensors. Due to its large magnetic moment and small absorption coefficient in the visible and infrared range, Tb3+ions have become commonly used rare earth ions in magneto optical glasses.

Terbium dysprosium ferromagnetostrictive alloy

At the end of the 20th century, with the deepening of the world scientific and technological revolution, new rare earth Applied Materials are emerging rapidly. In 1984, Iowa State University of the United States, Ames Laboratory of the United States Department of Energy of the United States and the U.S. Navy Surface Weapons Research Center (the main personnel of the later established American Edge Technology Company (ET REMA) came from the center) jointly developed a new rare earth Smart material, namely terbium dysprosium iron giant magnetostrictive material. This new Smart material has the excellent characteristics of quickly converting electrical energy into mechanical energy. The underwater and electro-acoustic transducers made of this giant magnetostrictive material have been successfully configured in naval equipment, oil well detection speakers, noise and vibration control systems, and ocean exploration and underground communication systems. Therefore, as soon as the terbium dysprosium iron giant magnetostrictive material was born, it received widespread attention from industrialized countries around the world. Edge Technologies in the United States began producing terbium dysprosium iron giant magnetostrictive materials in 1989 and named them Terfenol D. Subsequently, Sweden, Japan, Russia, the United Kingdom, and Australia also developed terbium dysprosium iron giant magnetostrictive materials.

From the history of the development of this material in the United States, both the invention of the material and its early monopolistic applications are directly related to the military industry (such as the navy). Although China’s military and defense departments are gradually strengthening their understanding of this material. However, after China’s Comprehensive National Power has significantly increased, the requirements for realizing the military competitive strategy in the 21st century and improving the level of equipment will certainly be very urgent. Therefore, the widespread use of terbium dysprosium iron giant magnetostrictive materials by military and national defense departments will be a historical necessity.

In short, the many excellent properties of terbium make it an indispensable member of many functional materials and an irreplaceable position in some application fields. However, due to the high price of terbium, people have been studying how to avoid and minimize the use of terbium in order to reduce production costs. For example, rare earth magneto-optical materials should also use low-cost dysprosium iron cobalt or gadolinium terbium cobalt as much as possible; Try to reduce the content of terbium in the green fluorescent powder that must be used. Price has become an important factor restricting the widespread use of terbium. But many functional materials cannot do without it, so we have to adhere to the principle of “using good steel on the blade” and try to save the use of terbium as much as possible.

Post time: Jul-05-2023