Brief introduction

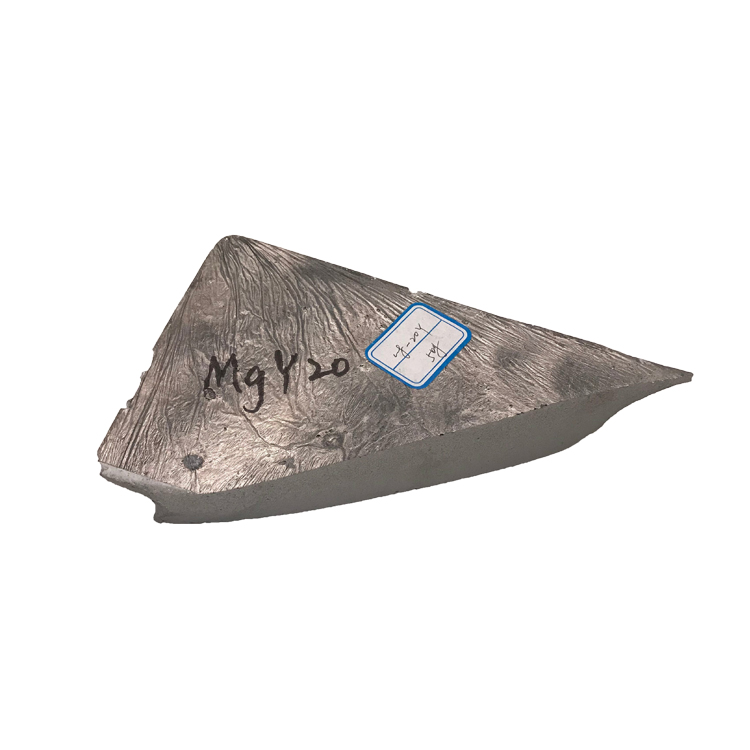

Product Name: Magnesium Yttrium Master Alloy

Other Name: MgY alloy ingot

Y content we can supply: 20%, 25%, 30%, 60%, 85%, customized

Shape: irregular lumps

Package: 50kg/drum, or as you required

Yttrium can be used as additive in magnesium alloy. Therefore, the Mg-Y master alloy can not only reduce the oxidation loss and cost, but also has the advantages of convenient storage and transportation, simple operation, pollution-free, stable composition and reliable quality. Magnesium yttrium alloy has low specific gravity (no more than 1.9g / cm3) and high strength, so it is widely used in aerospace industry to improve the heat resistance, corrosion resistance and high temperature strength of magnesium alloy.

| Name | MgY-20Y | MgY-25Y | MgY-30Y | |||

| Molecular formula | MgY20 | MgY25 | MgY30 | |||

| RE | wt% | 20±2 | 25±2 | 30±2 | ||

| Y/RE | wt% | ≥99.9 | ≥99.9 | ≥99.9 | ||

| Si | wt% | <0.03 | <0.03 | <0.03 | ||

| Fe | wt% | <0.05 | <0.05 | <0.05 | ||

| Al | wt% | <0.03 | <0.03 | <0.03 | ||

| Cu | wt% | <0.01 | <0.01 | <0.01 | ||

| Ni | wt% | <0.01 | <0.01 | <0.01 | ||

| Mg | wt% | Balance | Balance | Balance | ||

Magnesium Yttrium Master Alloy is widely used in the aerospace industry to improve the heat resistance, corrosion resistance and high temperature strength of magnesium alloys. Purification function, yttrium can remove impurities such as hydrogen, deoxidation and iron, reduce porosity and porosity of castings, and improve fluidity. The grain and dendrite are refined by modification. Yttrium has a high age hardening effect in magnesium alloy, which improves the room temperature strength. The addition of yttrium has better heat resistance and high temperature creep resistance than the addition of other rare earth elements. The working temperature is increased to 350℃. The addition of yttrium can improve the corrosion resistance of magnesium alloy.

We are manufacturer, our factory is located in Shandong, but we can also provide one stop purchasing service for you!

T/T(telex transfer), Western Union, MoneyGram, BTC(bitcoin), etc.

≤25kg: within three working days after payment received. >25kg: one week

Available, we can provide small free samples for quality evaluation purpose!

1kg per bag fpr samples, 25kg or 50kg per drum, or as you required.

Store the container tightly closed in a dry, cool and well-ventilated place.

-

Magnesium Erbium Master Alloy MgEr20 ingots man...

-

Magnesium Samarium Master Alloy MgSm30 ingots m...

-

Magnesium Lanthanum Master Alloy MgLa30 ingots ...

-

Magnesium Holmium Master Alloy MgHo20 ingots ma...

-

Magnesium Scandium Master Alloy MgSc2 ingots ma...

-

Magnesium Gadolinium Master Alloy MgGd20 ingots...